Cerabyte uses ceramic nanolayers creating the most reliable data storage ever. Data is save in a wide temperature range of -273°C (-460 °F) to 300°C (570°F) and even in corrosive or acidic atmosphere. Also radiation and an EMP can’t destroy information stored on Cerabyte. This means safe storage for generations.

Key Points:

- Cerabyte is a startup that develops archival data storage using QR codes in a nanoscale ceramic layer on glass platters.

- The platters are stored in cartridges, which are placed in drawers within a rack, similar to a tape library.

- The system uses a robot picker and mover to transport cartridges to and from a read/write rack.

- Blocks & Files visited Cerabyte at the LightFab facility in Germany, where a prototype system has been built with standard parts and materials.

- Cerabyte is a startup that uses laser and camera to write and read data on glass carriers with QR codes, stored in cartridges and racks.

- It has built a prototype system in Germany and plans to build a pilot product next year with higher capacity and speed.

- It has patented its technology and secured seed funding from investors, including Intel Ignite.

- It claims to have advantages over tape and disk archives in terms of durability, energy efficiency, and access time.

- It faces competition from Folio Photonics, which uses optical disks with fluorescent dots.

The prototype Cerabyte archival system is a pointer towards a pilot production system with the full product likely storing petabytes of data with faster-than tape access and tape library-class energy needs.

The startup is developing archival data storage based on data laser-written as Quick Response (QR) codes in a nanoscale ceramic layer coating a glass square platter or carrier that will be stable for thousands of years. The platters are stored in cartridges, akin to LTO tape reel cartridges, which are then placed in drawers within a rack, similar to a tape library. This is fitted with a robot picker and mover to transport cartridges to and from a read/write rack.

Blocks & Files visited Cerabyte at the LightFab facility in Aachen, Germany. Lightfab is a specialist in high-precision laser systems and 3D laser printing and ablation of fused silica glass. A prototype Cerabyte archive library system has been built there with LightFab’s machine building expertise and Cerabyte´s know-how based on femtosecond laser matrix technology and patented Ceramic-on-Glass data carriers playing a major role. playing a major role.

It is a full size, rack-scale system with cartridge-storing robotic system library racks and attached read/write rack. This prototype system is built from commercially available standard parts, and CEO Christian Pflaum said that the component supply chain did not have any single source supplier bottlenecks. All the materials and components involved are in large-scale production.

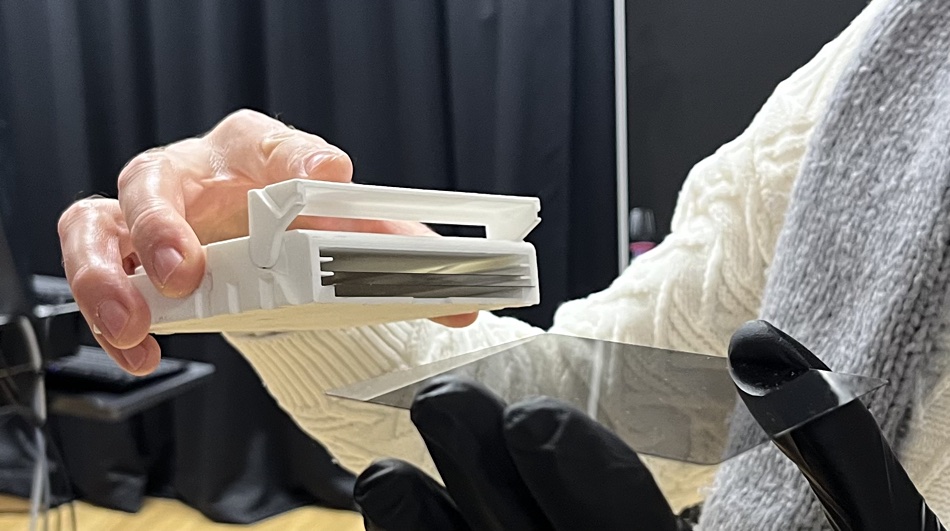

We saw the glass carriers and their bar-coded cartridge being loaded into a drawer, its label read, and the cartridge transported to the read/write rack for reading.

A cartridge holds three glass carriers which are slid into shelves inside the LTO-size cartridge. Cerabyte envisages a ten-carrier cartridge in a next iteration, with 100 carriers in a production system.

Twenty cartridges are stored in a drawer, with 30 drawers making up a total capacity of 600 cartridges per rack. The library racks have left and right columns of cartridge drawers with a space between them for the robot picker to enter, grip a cartridge, slide it out of its drawer and transport it to the read/write rack.

The cartridges have barcoded labels so that the system controller can identify them and know their location. Once a cartridge has been selected for reading or writing, it is picked up by the robot system, located at the rear of the library rack, and transported to the read/write rackby a conveying system.

When it is at its destination, a separate robotic system extracts the requisite glass carrier from the cartridge and, using a four-spot gripper, moves it to a platform in the read/write station. This is somewhat simpler than threading a tape ribbon into a read/write drive.

<iframe title=”vimeo-player” src=”https://player.vimeo.com/video/841629751?h=18b88b89e6″ width=”640″ height=”360″ frameborder=”0″ allowfullscreen></iframe>

The read/write station is fitted atop a damping system to screen out vibrations.

Once on the platform, it can be moved left to right and in and out to position it under the laser or camera. Thus its contents can be written using the femtosecond laser or read using a microscope camera. Data is written using a laser beam matrix and a Digital Mirror Device (DMD).

The DMD is the core invention enabling Cerabyte’s write speed and was devised by Pflaum and a Vienna University of Technology team.

When that process is completed, the carrier will be placed back on its cartridge and the cartridge transported back to its drawer. We’ve gone into some level of detail here to show that the prototype system and its component are functional.

Pflaum said Cerabyte envisaged a pilot product with a 1 PB-per-rack capacity and 90-second access to data being built next year. Cartridge density can be improved by using smaller bit sizes (dots) and both surfaces of the carrier, and a gen 2 QR that encodes more data. A fourth avenue is using two-dimensional write shingling with some academic papers discussing this technique. A fifth avenue is using particle beam devices instead of femtosecond lasers to achieve even smaller dots as well as potentially parallelizing writing by having multiple particle beam electron guns. Cerabyte’s technology roadmap envisages TBps read/write speeds by 2050, exabyte-per-rack capacity levels, and access time down to five seconds.

Cerabyte is patenting the crucial parts of its technology with several patent filings completed. Pflaum said the patents, in a territorial sense, covered 80 percent of global GDP, even in Japan.

Its next major task is to build a pilot product and then move into full productization. That may well require a step forward into VC-class funding as its current seed investor funding of around $7 million will probably not be sufficient. Its investor list includes Daniel Aegerter as the lead investor plus Porsche’s Sajjad Khan, who is chairman of Cerabyte’s board. The company is a participant in the Intel Ignite accelerator program.

NASA Awards Turbofan Engine Core Technology Demonstration Contract

Technology News and Trends: AI, Storage, Supercomputing and The Vast Potential

Datacenter Infrastructure Report Card, Q3 2023

Why is making artificial saliva so hard?

Cerabyte Aims to Revolutionize Data Storage With Nanodots on Ceramic

Tachyum 8 AI Zettaflops Blueprint to Solve OpenAI Capacity Limitation

This prototype Cerabyte system, built using readily available standard components, indicates that Cerabyte’s technology can be productized and manufacturing volume scaled up. Its roadmap shows that it has good potential for increasing capacity and data access speed. The crucial next stage is building a pilot product from which to measure actual capacity per carrier and per rack, and actual read and write speeds.

We think Cerabyte is closer to building a product than Folio Photonics which is developing 8-16 layer spinning optical disk technology using bleached or unbleached fluorescent dots to carry binary data signals. After showing its technology works in lab conditions it has to build an optical archive drive. This could be a tougher technical task than developing Cerabyte’s system. Folio P has raised $12.6 million in four rounds from VC investors.

The Cerabyte system promises to provide greater-than-tape library rack capacity, much longer endurance than tape, and with no media resilvering needed. It will use far less energy than a constantly spinning disk archive and potentially have faster data access than a spun-down disk library, as well as weighing less. We look forward to seeing what a pilot product can do.

Blocks & Files is a storage news, information and analysis site covering storage media, devices from drives through arrays to server-based storage, cloud storage, networking and protocols, data management, suppliers and standards. We publish news, views, opinions and analysis of storage industry events and developments, aiming to keep storage users, developers, consultants, marketeers, salespeople, support staff, analysts and everyone else involved in IT storage up to date with what’s going on.

Source: Blocks and Files Cerabyte Ceratype archival system store petabytes of data faster-than tape access tape library-class energy needs